WEBgui

QRcode connection

| IP client example http://xx.xx.xx.xx |

Hotspot example PUMPwlan123456 |

|

|---|---|---|

|

|

|

| connect to URI fluidicworks.com |

connect to SSID with pwd |

for a conveniant browser access, pls. open the QRcode application of your smartphone and scan the QRcode which is shown on the OLED display. The QRcode will be shown at startup automatically or it can be retrieved at any time by activating the IPshow function under the Services (SVC) Menu.

The pump can work in different access modes:

- regular IP client with Ethernet connection (DHCP service supplied by customers router)

- regular WLAN IP client (with correct WLAN configuration and DHCP service)

- as WLAN Hotspot (pump will act as WLAN router, clients can connect to hotspot pumpWLANxxxxxx)

- as WLAN Hotspot with working Ethernet connection

If pump is working as regular IP client, QRcode will connect to assigned IP-Address

If pump is working as Hotspot only, QRcode will connect to pumpWLANxxxxxx

Configuration options can be found in the Setup menu under WLAN and WLANhotspot tabs.

Start menu

To open the start page, pls. use one of the links below:

https://pump.local or

https://<ipaddress>

From this page, you can view documentation and start pumps WEBgui.

Pls. accept pumps self signed certificates.

Dashboard

The Dashboard (Dashb) gives the user access to mainly used functions and information for direct and fast usage.

P1 - P6: will show the SetPoint (SetP) and the actual pressure - process value (PV) for each licensed reservoir.

The pressure value can be set for each reservoir individually.

Orange colored reservoirs e.g. P1 indicate positive pressure reservoirs.

Blue colored reservoirs e.g. P3 indicate vacuum reservoirs.

All available macros can be selected from the macro pull down menu and started with the [Exec] button.

Different run modes like Operation [Oper], Standby [Stby], [AllOff] and injecting Solution[1-4] can also started from the Dashboard.

[Help] button will open a new browser tab with help information.

Menu button

By activating the menu button (☰), a navigation menu will appear.

By selecting a menu entry or by pushing the button again, the menu will disappear.

Slider menu

The Slider menu can directly reached from the Dashboard by pressing the [Slider] button. Each slider can control a set of reservoirs at once. With each [de-/sel] button a set of reservoirs can be composed for each slider. A reservoir set is indicated by magenta colored mbar units. Slider movements will control each pressure proportionally of each reservoir set.

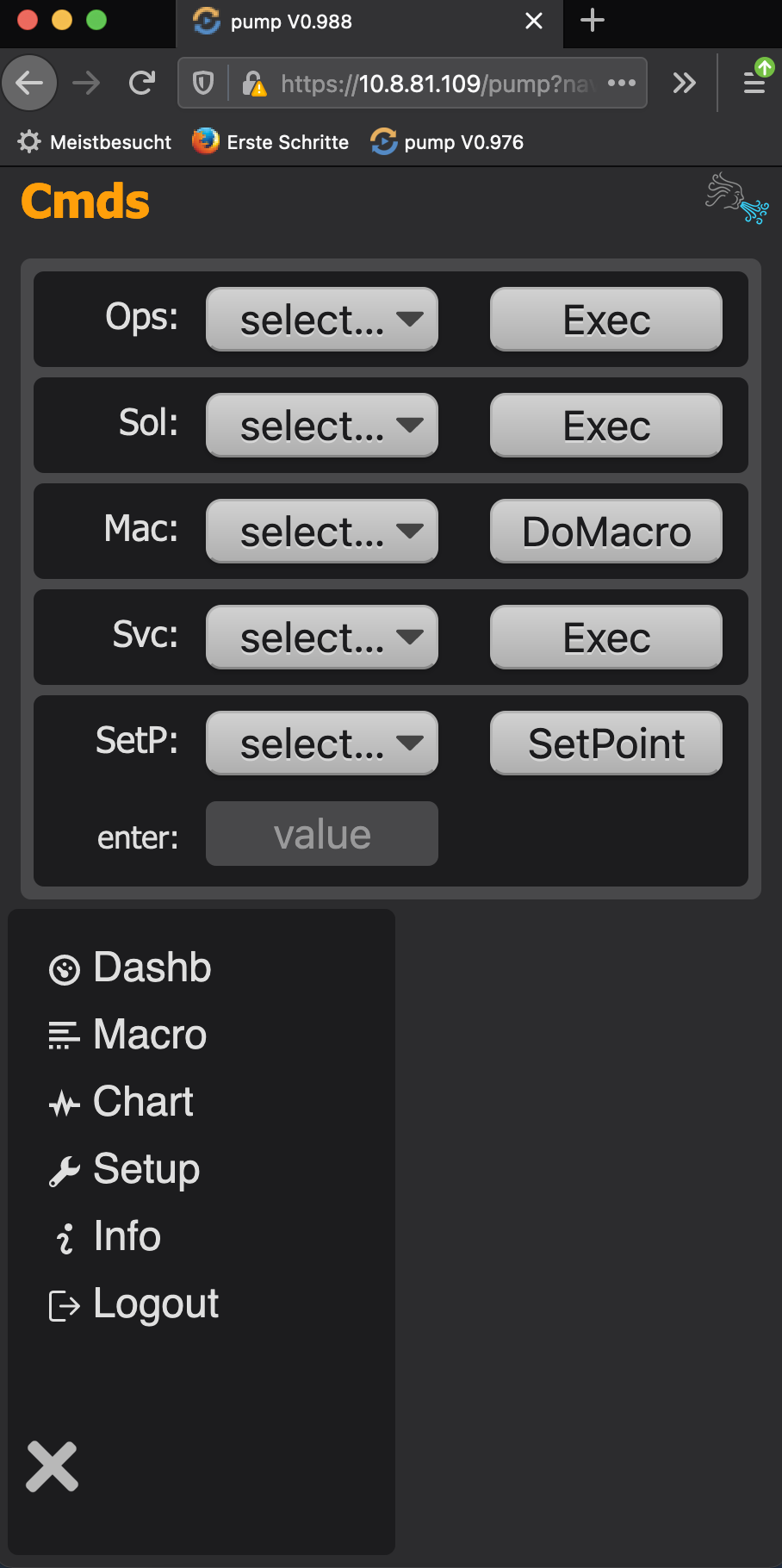

Control menu

The Cntrl menu offer the usage of all functions on one page.

Activation by selection of desired function from pull down menu and start with [exec] button.

Chart menu

This page will give information about pump performance and leak rates of each reservoir.

The graphic is interactive in selecting the time range and average span.

Setup menu

In the Setup menu, you will find different sections (like HOME, PUMP …) to configure the device fitting your environmental needs.

[HOME] section:

Owner specific information (e.g. company name, dept.)

[PLATFORM] section:

Configuration of timezone, hostname, loglevels …

[PUMP] section:

Pump specific setup like enable/disable TCP server socket port …

[LICENSE] section:

enter license information

[SMTP] section:

enter mail server configuration

[WLAN] section:

for entering WLAN configuration data. Your pump will connect to your local WLAN.

[WLANhotspot] section:

The system can offer WLAN hotspot functionality.

Info menu

On this page you will find several technical and licensing information.

Macro menu

The macro menu shows up to 20 macro scripts, which are stored in the macro directory of your device. Macros can be exported and imported to/from an USB stick or via FTP protocol.

To create a new macro via the WEBgui, just type in a new filename and click the [Create] button.

Uploading a local filename.macro by a browser is possible by using [Choose file] and [Upload] buttons.

Opening a specific macro for inspection or editing, just click the [macroname] tab.

Save your script by using [update].

Browser support

| Chrome | Edge | IE | Firefox | Safari | Opera |

|---|---|---|---|---|---|

| YES | ok | no | YES | ok | ok |

Command reference

[Format]

<command> <param1>[,<param2>,...]

<command> (<param1>[,<param2>,...])

Example:

setP 1,220 # format #1: recommended format

setP (1,220) # format #2: pls. do not useDue to compatibility reasons, parameter can be surrounded by rounded brackets ( )

Recommended format: without rounded brackets, shown in format #1.

[Parameter]

Parameters are separated by , (comma).

Commands are NOT case sensitive.

Labels are case sensitive.

Parameter types:

<register>: -1,0,1,...9

e.g. REG-1,REG9

<integer>: -1,0,1,2,3 ...

<float>: -1.234,3.1415 ...

<number>: <integer>, <float>

e.g. -1,1.234 ...

<label>: Alphanumeric (ASCII Characters [0x20..0x7e], [space..~])

e.g. Label1

<text>: Alphanumeric (ASCII Characters [0x20..0x7e], [space..~])

text can be unicode encoded e.g. H\u2082O temp 25\u00b0C

<setstrng>: 0,x,1

0:ON; 1:OFF;

x:unaffected

errorlevel in REG-1:

every macro command will set an errorlevel

0: command execution was successful

-1: command execution was not successful

positive levels and zero (>=0) can be

interpreted as successful command execution.

negative levels (<0) can be interpreted

as unsuccessful command execution.Controlling the macro command sequence by errorlevel, using JS and JNS is recommended.

Example:

# Begin of Macro

DoMacro SetMyDefaults

MOV 1,5

Label Loop

SerWrite /dev/ttyUSB0 go next

JS -1,HndlErrRead

#

# Do some microfluidic stuff

#

DEC 1

JNZ 1,Loop

JMP EndMacro

Label HndlErrRead

TEXT Error\nReading device

Label EndMacro

# End of Macroanalog/digital IO

AOut

Set Analog (DAC) Output

An optional module is required.

AOut <channel>,<vrange%>

Parameter:

DAC channel: 1 - 4

vrange%: 0 - 1.0 (0V - 5V)Example:

AOut 2,0.50 # Set DAC2 Output to 50% of

# available voltage range (-> 2.5V) DOut

Set Digital Output

DOut <port>,<level>

Parameter:

Port: 1 - 4

Level: 0 or 1Example:

DOut 2,1 # Set Port 2 to highDOutM

Set available Dout ports On/Off at once

DOutM <setstring>

Parameter:

Ports: 1 - 4

0: OFF

1: ON

x: unaffectedExample:

DOutM 0,x,1,0will set port #1,4 OFF; let port#2 unaffected; set port#3 ON

Play

Play a file (.mp3 .wav) on audio output (3.5mm jack).

file resides in macro directory.

An optional module is required.

Play <file>

Example:

play testfile.mp3SetRelais

Set available Relais On/Off.

An optional module is required.

setRelais <setstring>

Parameter:

Relais: 1 - 3

Relais 3: switches HighVoltage ON / OFF

0: ON

1: OFF

x: unaffectedExample:

setRelais 0,x,1 # set Relais#1 OFF

# let Relais#2 unaffected

# set HighVoltage ONSyncOut

Generate a trigger pulse on available Output.

syncOut [<outpin>,]<pulselength>

Parameter:

TriggerOut: 1 - 2

PulseLength: 1 - 100 msecExample:

syncOut 2,50 # 50msec pulse on trigger out #2

syncOut 75 # 75msec pulse on trigger out #1WaitSync

Wait for a trigger pulse on available Input.

waitSync <inputpin>,<waveform>[,<timeout>]

Parameter:

TriggerIn: 1 - 2

WaveForm: RISE or FALL

Timeout: >=0 secondsExample:

waitSync 2,RISE # wait on rising pulse on trigger in #2

waitSync 1,FALL,60 # wait on falling pulse on trigger in #1,

# timeout 60 secondsX10

Set X10 general purpose (GPIO) output.

X10 <ON|OFF>

Parameter:

ON or OFF: (default: OFF)Example:

X10 ON # set GPIO output HIGH,

# if configured as OUTPUT

X10 ON # enable frequency on GPIO output,

# if configured as frequency OUTPUT

X10 OFF # set GPIO output LOW,

# if configured as OUTPUT,

# or disable frequencyX10mode

Set mode of X10 general purpose (GPIO) output

X10mode <OUTPUT|frequency_Hz>

Parameter:

OUTPUT: configure as output (default: OUTPUT)

<frequency_Hz>: 4690 - 19200000 (4690Hz - 19.2MHz)Example (sequence 1):

X10mode OUTPUT # set GPIO to output

X10 ON # set output level HIGH

sleep 10 # wait 10 secs

X10 OFF # set output level LOWExample (sequence 2):

X10mode 5500 # set output frequency to 5500Hz

X10 ON # switch frequency on,

# set in previous command

sleep 10 # wait 10 secs

X10 OFF # switch frequency offBackup/Restore

files are stored in directory ~/bck

filename will contain backup type, device serial number and timestamp.

filename format:

bck<type>_<snr>_<timestamp>.tgz

type:

cfg configuration backup data

exe application backup

timestamp: YYYYMMDDhhmmss (e.g. 20181006234505)CreaCfgFil

create backup file (bckcfg_<snr>_<timestamp>.tgz) of configuration data.

CreaCfgFil

RstCfgFil

restore latest config file which was created with CreaCfgFil

RstCfgFil

Support File

files are stored in directory ~/maint

filename will contain devices serial number and ssl identification.

file ist encrypted by ssl certificate.

filename format:

supportfile_<snr>.tgz.<sslID>.ssl

sslID: <hexstring> (e.g. 3a...e5)CreaSupFil

create support file which contains log data.

The file can be uploaded with UplSupFil

CreaSupFil

UplSupFil

upload ssl encrypted support file with was created by CreaSupFil

UplSupFil

DC/Stepper Motor

DCMfreq

DC motor frequency in Hz

DCMfreq <freq_Hz>

Parameter:

freq_Hz: 10 - 2000 (default: 1000)Example:

DCMfreq 1000 # motor freq 1000HzDCMpwm

DC motor PWM dutycycle

DCMpwm <dutycycle%>

Parameter:

dutycycle%: 0 - 1.0 (default: 0)Example:

DCMpwm 0 # motor is OFF

DCMpwm 0.5 # motor dutycycle 50%.

# Turns with half speed

DCMpwm 1 # motor is ON.

# Turns in full speedSTPdir

Stepper motor set direction

STPdir <LEFT|RIGHT>

Example:

STPdir LEFT # motor should turn left

STPdir RIGHT # motor should turn right (default)STPenable

Enable/Disable stepper motor

STPenable <0|1>

Example:

STPenable 0 # motor will stop movement (default)

STPenable 1 # motor will start movementSTPmode

Set step mode

STPmode <stepmode>

Parameter:

stepmode: 0 - 4

0: full step

1: half step

2: 1/4 step (default)

3: 1/8 step

4: 1/16 stepExample:

STPmode 3 # set motor to 1/8 step

STPmode 0 # full stepSTPrev

Set stepper motor revolution (steps per turn in full step)

STPrev <stepsperturn>

Parameter:

stepsperturn: 10 - 40000 (default: 200)Example:

STPrev 200 # resolution is 1.8 degree per step

# 200 steps per turnSTPsleep

Set stepper motor to sleep/ready modus

STPsleep <number>

Example:

STPsleep 0 # motor will be set to sleep mode

STPsleep 1 # motor will be set to active mode

# (activate charge pump, takes some msec)STPspeed

Stepper motor speed in Hz

STPspeed <speed_Hz>

Parameter:

speed_Hz: 10 - 800 (default: 400)Example:

STPspeed 400 # motor speed 400Hz

STPspeed 100 # motor speed 100HzSTPrun

Set run time in seconds (sec)

STPrun <runtim_sec>,<timeout_sec>

Parameter:

runtim_sec:

>0: motor will turn <runtime_sec> seconds

0: motor will turn continuously

-1: motor will turn until switch#1

position reached.

-2: motor will turn until switch#2

position reached.

-3: motor will turn until switch#1

or switch#2 pos. reachedExample:

STPrun 2.5 # motor turns 2.5 secs

STPrun 0 # motor turns continuously

STPrun -3,1.0 # motor turns until switch#1 or #2

# position reached or timeout of 1secSTPturn

Set amount of rotations/turns

STPturn <rotations>

Example:

STPturn 0.75 # 3/4 turnExample (macro):

mov 1,5 # 5x loop

LABEL LAB1

sleep 1

STPDir LEFT # motor direction Left

STPspeed 800 # set speed to 800Hz (fast)

STPTurn 5 # do 5 turns

STPspeed 400 # set speed to 400Hz

STPTurn 0.75 # do a 3/4 turn

STPspeed 50 # speed 50Hz (slow)

STPTurn 0.20 # 1/5 turn

STPspeed 10 # very slow

STPTurn 0.05

STPDir RIGHT # do same action to the right

STPTurn 0.05

STPspeed 50

STPTurn 0.20

STPspeed 400

STPTurn 0.75

STPspeed 800

STPTurn 5

sleep 2 # wait 2 secs

dec 1

jnz 1,LAB1 # Jump to label LAB1 5 times

text FINISH # show FINISH on OLED displaySERVO

Turn servo to defined angle, or enable/disable DB9 pin for servo mode

SERVO <num>,<disable|enable>[,<profile>]

SERVO <num>,<angle>[,sync]

Parameter for setup:

disable: set DB9 X1 pin to (STP/DCM) motor mode (default)

enable: set DB9 X1 pin to servo modeservo profile parameter (predefined):

DFLT: # 50,180,-90,90, 800,2200

SG90: # 50,100,-90,90, 600,2600

MG90S: # 50,100,-90,90,1000,2000

MG996R: # 50,170,-60,60,1000,2000servo profile parameter (by user definition):

USR,<freq>,<waittime>,<ANGmin>,<ANGmax>,<DTYmin>,<DTYmax>

USR: indicator for user defined profile

freq: PWM frequency in Hz (e.g. 50)

waittime: time in ms, servo needs for 60 degree (e.g. 180)

ANGmin: minimum angle, left position in degree (e.g. -90)

ANGmax: maximum angle, right position in degree (e.g. 90)

DTYmin: duty cycle for minimum angle in microsec (e.g. 800)

DTYmax: duty cycle for maximum angle in microsec (e.g. 2200)Parameter for operation:

num: 1 - 2 # use Servo pin #1 or #2

angle: -90 ... 90 # integer position -90:left 0:middle 90:right

sync: 1 # sync on, until servo has reached new positionExample:

SERVO 2,enable,SG90 # set DB9 X1 pin to servo2 mode with SG90 profile

SERVO 1,enable,USR,50,180,-90,90,800,2200 # user defined profile

# enable/disable is needed only once per servo

SERVO 2,-45,1 # turn Servo#2 to -45 degree, wait until finishedFirewall

pump uses firewalld (FWD) to implement network security.

Configuration changes executed through Setup menu e.g. opening/closing ports for SCPI, MQTT or WebSRV access, limiting access via allow lists, will need reconfiguration of firewalld rules. If the pump detects that changes to the ruleset become necessary, it will notify the user with a corresponding message on the Dashboard and urges to execute the FWD apply command.

FWD apply

Apply configuration changes and configure firewalld rules.

FWD apply

This command will trigger a whole bunch of commands to configure firewalld’s ruleset. The execution takes place in the background and requires about 20 seconds. The ruleset of all active zones can be evaluated on Info menu under the [firewall (active rules)] tab.

public (active)

target: default

icmp-block-inversion: no

interfaces: eth0 wlan0

sources:

services: dhcpv6-client ftp http https mdns ssh upnp-client

ports:

protocols:

forward: no

masquerade: yes

forward-ports:

source-ports:

icmp-blocks:

rich rules:

rule source mac="8C:85:90:12:34:56" port port="5025" protocol="tcp" accept

rule family="ipv4" source address="10.8.81.100" port port="5025" protocol="tcp" accept

trusted (active)

target: ACCEPT

icmp-block-inversion: no

interfaces: ap0

sources: 10.3.141.0/24

services:

ports:

protocols:

forward: no

masquerade: no

forward-ports:

source-ports:

icmp-blocks:

rich rules: This ruleset will show, that network client access on ethernet (eth0) and wireless lan (wlan0) is allowed for the following protocols:

public zone:

- DHCP: assign IP6 address to pump on request. rule for IP4 not needed, already enabled

- ftp: FTP server process is running on pump, this rule will give clients access

- http: clients can access WEBgui through webserver standard port 80

- https: clients can access WEBgui through webserver standard port 443

- mdns: Avahi/Bonjour protocol. mac/linux clients can discover pump more conveniant

- ssh: will give administrators remote access

- upnp: plug and play protocol, conveniant network client access

- 5025: SCPI port, e.g. for LABview integration and remote control for two specific clients only, which are defined by IP address 10.8.81.100 and a device with mac address 8C:85:90:12:34:56. Limiting access for specific clients can be achieved by maintaining the SCPI Allow comma-separated (csv) list (e.g. 10.8.81.100,8C:85:90:12:34:56)

Clients connected on Hotspot wlan service (interface ap0) will be treated as trusted.

trusted zone:

all clients with an IP address within the 10.3.141.0/24 subnet have unlimited access.

Macro Control

<register>

The system offers 10 registers numbered [0..9] which are read and writeable by several macro commands (e.g. mov, dec, inc, jnz …). They act globally and can be used to pass results to/from a called macro to the calling macro (pls. see DoMacro command).

<errorlevel>

The numbered register -1 represents the errorlevel of a preceding macro command. This register is read only.

ask

Will ask for user response. A question will be displayed on the OLED. The response can be given by the encoder wheel.

ask[<askType>,<TimeOut>,<TimeOutDefault>,[<TargetRegister>,]]<Question>

Parameter:

askType: <YesNo,Integer,float1,float2>

Question: that will be displayed on the OLED

TimeOut: If an answer is not given within the

<timeout> seconds (default 60),

TimeOutDefault: will be used.

TargetRegister: Answer will be stored in an

internal counter register.

Shortcuts for Question:

ask_to_continue AskType: YesNo

TimeOut: 60

TimeOutDefault: 0

Question: Continue?\n(Yes/No)

ask_for_passes AskType: Integer

TimeOut: 60

TimeOutDefault: 0

Question: Passes?Example:

ask ask_to_continue # Will ask for Yes or No.

ask YesNo,60,0,Continue?\n(Yes/No) # same as above

# TimeOut 60sec

# Default answer 0 (No),

# a jump to the end of

# the macro will be

# executed.

ask YesNo,30,1,Continue?\n(Yes/No) # If answer is not given

# within 30 secondes,

# 1 (Yes) will be given.

ask ask_for_passes # Will ask for a number

# and stores the result

# into Register0.

# TimeOut 60 sec

ask Integer,20,5,0,Passes? # Will ask for a count

# and stores the result

# into Register0.

# If answer is not

# given within 20 sec.

# A count of 5 will be

# stored into Register0.

# Remark: \n

# insert Linefeed (LF)DoMacro

Call a Macro within a Macro. Acts like calling a subprogram. The intention is, to define common information in a central place, which can be used by any other macro.

Macros have the file extension .macro and are stored in directory ~/macro

DoMacro <macroname>

Example:

Macro MyMacro1:

beep 5

# set some defaults, pon poff ...

DoMacro SetMyDefaults

oper

sleep 1

# do some stuff ...Macro SetMyDefaults:

SetPON 220

SetPOFF 24

alias LabTable,/dev/ttyUSB2

setTTY LabTable@115200 -cstopb -parenbcmp

Compare register content with a value.

Compare register-content1 with register-content2.

cmp <register>,<value>

cmp <register1>,<register2>

Example 1:

mov REG1,3 # fill register1 with value 3

cmp REG1,5 # compare content of register1

# (value=3) with value 5

# errorlevel: -2 (3-5)Example 2:

mov REG4,3 # fill register4 with value 3

mov REG7,5 # fill register7 with value 5

cmp REG4,REG7 # compare content of reg4 (3) with reg7 (5)

js REG-1,LAB # will jump (jmp on sign) to LAB

# errorlevel: -2 (3-5)

# (because result is negative)dec

Decrement register content by a value.

dec <register>[,<value>]

Example:

dec REG1 # decrement register 1 by 1

dec REG1,2 # decrement register 1 by 2inc

Increment register content by a value.

inc <register>[,<value>]

Example:

inc REG1 # increment register 1 by 1

inc REG1,2 # increment register 1 by 2jmp

Jump (unconditional).

jmp <label>

Example:

jmp Loop1 # jump to Label Loop1jnz

Jump if register content is non zero.

jnz <register>,<label>

Example:

jnz REG1,Loop1 # jump to Label Loop1,

# if register 1 content is not 0jz

Jump if register content is zero.

jz <register>,<label>

Example:

jz REG1,Loop1 # jump to Label Loop1,

# if register 1 content is 0js

Jump if register content is negative (jumpOnSign).

js <register>,<label>

Example:

js REG1,Loop1 # jump to Label Loop1,

# if register 1 content is <0jns

Jump if register content is positive (jumpOnNOTSign).

jns <register>,<label>

Example:

jns REG1,Loop1 # jump to Label Loop1,

# if register 1 content is >=0Example (macro with control structures) :

# remark

ask Integer,20,5,0,Passes? { multiline comment:

store answer in register0.

TimeOut is 20 secs.

Default value 5 }

Label Loop1 # jump label

#

# do something else

# ...

dec REG0,1 # decrement register 0 by 1

jnz REG0,Loop1 # jump to Loop1,

# if register 0 <>0

pumpsOff # continue here,

# if register 0 = 0

text DONE!!! # show DONE!!! on OLED Displaylabel

Places a jump target within a macro.

labelstring is case sensitive.

label <labelstring>

Example:

label Loop1sleep

command sequence will sleep for <number> seconds.

sleep <number>

Example:

sleep 5 # sleep for 5 secs

sleep 1.2 # sleep for 1200 millisecs mov

Move a numerical value to a register.

Move a value from register source to register target.

mov <regtarget>,<number>

mov <regtarget>,<regsource>

Example:

mov 3,5 # move value 5 into register 3

mov REG3,5 # move value 5 into register 3

mov REG1,REG3 # move content of register 3 (5)

# to register 1 testmode

Command sequence will be set to testmode. All pressure manipulating commands will not be executed (e.g. AllOff). Only flow control commands like JNZ, DEC, INC and sleep commands will be executed. The intention of this command is to analyze and observing the behavior of a Macro for testing purposes. Testmode will be inherited from the calling macro to all subsequent called macros.

testmode

Example:

TestMode()

setVswitch(-200) # will not be executed

sleep(5)

setVswitch(-10) # will not be executed

sleep(2)

solution1() # will not be executed

sleep(5)

solution3() # will not be executed

sleep(10)

allOff() # will not be executed

ask(Continue?\n(Yes/No))

solution2() # will not be executed

sleep(10)

allOff() # will not be executed

pumpsOff() # will not be executed

text(DONE!!!)msg

A message will be displayed in the web gui.

msg [<level>,]"<text>"

Parameter:

| level | text color | error level |

|---|---|---|

| ERR | red | ERROR |

| WRN | yellow | WARNING |

| SUC | green | SUCCESS |

| INF | white | INFO (default) |

| URG | red | URGENT |

| MAG | magenta | |

| RED | red | |

| ORA | orange | |

| YLW | yellow | |

| GRN | green | |

| LGR | light green | |

| BLU | blue | |

| BLK | black | |

| WHT | white |

Example:

msg "a Text" # display 'a Text' in web gui

msg blu,"Line1\nLine2" # display use 2 lines, color blue

msg mag,"info ""text""" # display 'info "text"' in magenta

msg "H\u2082O temp 25\u00b0C" # display H2O temp 25C (unicode)last example will display: H2O temp 25°C

text

A message will be displayed on the OLED.

text[<DisplayTimeInSecs>,]<text>

Example:

text aText # display 'aText' on OLED for

# 5 sec (default)

text 10,Line1\nLine2 # display 10 sec 'Line1' on first

# line and 'Line2' on 2. LinewaitTime

Wait until given time has reached.

waitTime <XMLDateTimeStamp>

Example:

waitTime 2018-07-10T14:28:15+02:00 # UTC: 12:28:15 10-Jul-2018

waitTime 2018-07-10T14:28:15-08:00 # UTC: 06:28:15 10-Jul-2018

waitTime 14:28:15+02:00 # UTC: 12:28:15 today

waitTime 14:28:15Z # UTC: 14:28:15 today

waitTime 14:28:15 # local time: 14:28:15 todayRequirement:

- TimeZone must be set accordingly

- NTP protocol will be used to adjust internal clock

- internet or RTC required for proper operationfurther information about XML TimeStamps:

http://books.xmlschemata.org/relaxng/ch19-77049.html

Pressure Control

AllOff

Pump will be set to Off Mode.

AllOff

Clean

Pump will be set to cleaning Mode.

clean [<integer>]

Parameter:

<integer> determines the amount of seconds

Maximum time: 10 seconds

default value: 2 secondsExample:

clean # cleaning time 2 secs

clean 8 # cleaning time 8 secsInit

Pump will be set to Initialize Mode.

init

Oper

Pump will be set to Operation Mode.

oper

SetMeassure

Set channel to meassure mode.

In this mode, the channel will meassure external connected pressure or vacuum.

Leave this mode with SetPoint (setP) function.

setMeassure <reservoir>

Parameter:

Reservoir: 1 - 8Example:

setMeassure 3 # Set reservoir 3 to meassure modeSetP

Set pressure/vacuum value (SetPoint) for available reservoir.

setP <reservoir>,<number>[,oper,stby,temp]

Parameter:

Reservoir: 1 - 8

Pressure SetPoint: 0 ... +500 (mbar)

Vacuum SetPoint: -300 ... 0 (mbar)

Profile: oper, stby, temp (default: oper)oper and stby will affect according profile.

temp will not affect any profile and is a temporary SetPoint.

Example:

setP 1,220 # SetPoint 220mbar for reservoir 1

setPON 220 # SetPoint 220mbar for reservoir 1

setP 3,-110 # Vacuum SetPoint -110mbar for reservoir 3

setVSwitch -110 # Vacuum SetPoint -110mbar for reservoir 4&5Reservoir pressure default values (mbar):

| Res | setAlias | Type | min | stby | oper | init | clean | max |

|---|---|---|---|---|---|---|---|---|

| #1 | setPON | 0 | 10 | 220 | 220 | 300 | 500 | |

| #2 | setPOFF | 0 | 10 | 20 | 500 | |||

| #3 | setVRecirc | Vacuum | -300 | -45 | -115 | 0 | ||

| #4 | setVRecirc2 | Vacuum | -300 | -10 | -115 | 0 | ||

| #5 | setVRecirc1 | Vacuum | -300 | -10 | -115 | 0 | ||

| #6 | setP6 | 0 | 110 | 500 | ||||

| #7 | setP7 | 0 | 110 | 500 | ||||

| #8 | setP8 | Vacuum | -300 | -115 | 0 | |||

| #4&5 | setVSwitch | Vacuum | -300 | -10 | -115 | 0 |

SetSTBY

Set Standby pressure/vacuum value for available reservoir.

setSTBY <reservoir>,<number>

Parameter:

Reservoir: 1 - 8

Pressure Standby: 0 ... +500 (mbar)

Vacuum Standby: -300 ... 0 (mbar)Example:

setSTBY 3,-45 # Standby pressure -45mbar

# for vacuum reservoir 3SolGroup

Accumulate operation on Manifold valves.

solGroup [0|1]

Parameter:

0 (OFF):

Selecting a specific solution, closes all other valves first

and open/close selected valve.

A transition from ON to OFF, all valves will be closed.

1 (ON):

Selecting a specific solution will open/close valve and

let other valves unchanged.

Indicated on OLED display with 'c'-flag.

not given:

Toggle: ON->OFF; OFF->ONSolution

switch solution<nr> OFF, ON or pulselength

solution <solnr>[,0|1][,<pulselength>]

solution<solnr> [0|1][,<pulselength>]

Parameter:

<solnr>: 1 - 6

0: OFF

1: ON (default)

not given: Toggle: ON->OFF; OFF->ON

pulselength:pulse in seconds (max. 2.0 seconds)Example:

solution1 # on channel 1, switch solution ON

solution 1 # on channel 1, switch solution OFF

solution1 0 # on channel 1, switch solution OFF

solution 1,1,0.3 # on channel 1, switch solution ON for 0.3 seconds

solution1 # on channel 1, toggle solution OFF

# (state before: ON)

solution1 # on channel 1, toggle solution ON

# (state before: OFF)StBy

Pump will be set to Standby Mode.

stby

WaveSet

Define a wave for SetPoints.

Waveforms (mode):

| Linear | Triangle | SawTooth | Square | Sinusoidal | S-shape |

|---|---|---|---|---|---|

|

|

|

|

|

|

| 0 | 1 | 2 | 3 | 4 | 5 |

WaveSet <reservoir>,<ivs>,<mode>,<cnt>,<startp>,<endp>[,dtyc]

Parameter:

reservoir: 1 - 8

ivs: Interval in seconds. Time between loading

next SetPoint.

cnt: count of intermediate SetPoint values

between <startp> and <endp>

startp: SetPoint start value.

endp: SetPoint end value.

dtyc: 0 - 1, duty cycle for square wave form

(optional).

e.g.: 0.75 -> 25% <startp>, 75% <endp>

mode: 0 - 5

0: linear SetPoint smooth increase from <startp> to

<endp> and remain.

1: triangle smooth oscillate between <startp> and <endp>

2: sawtooth smooth increase from <startp> to <endp>,

Falldown to <startp>

3: square Alternate between <startp> and <endp>,

influenced by <dtyc>

4: sinusoidal oscillation between <startp> and <endp>

5: S-shape oscillation between <startp> and <endp>

WaveSet <reservoir>,<ivs>,<fmode>,<filnam.wave>

Parameter:

filnam: load user specific wave form

fmode: determine idx movement within the wave.

0 -> after reaching last idx,

remain at last idx

1 -> after reaching last idx,

decrement idx by 1 until idx=0

2 -> after reaching last idx,

start at idx 0

filelocation: in ~/macro directory.

FileExtension is '.wave'

fileformat: one SetPoint value <number> per line.

e.g: 30.0 ... 105.0Wave

Enable/Disable Wave operation.

Wave <reservoir>,<0|1>[,startidx]

Parameter:

reservoir: 1 - 8

0: disable

1: enable

startidx: determine from which value will be used

first (optional, default 0)

e.g.: wave array with <cnt> 71 SetPoints

(30-100mbar).

<startidx> 36 uses 65mbar as first

SetPoint value.Example (macro):

WaveSet 1,0.5,0,71,30,100 # explanation see below

Oper # start pumps

Wave 1,1 # enable previously defined wave for reservoir 1

Sleep 45 # during 45sec, play out 71 SetPoints

AllOff # stop operationWaveSet Parameter (explained):

1: for reservoir 1

0.5: load next SetPoint every 0.5 sec (500msec)

0: use linear Ramp. After reaching 100mbar,

remain at 100mbar

71: use indexed value array with 71 SetPoints.

(idx: 0 - 70)

increase per SetPoint of 1mbar

(100-30)/(cnt-1)

30: start with SetPoint 30mbar

100: end with SetPoint 100mbar SCPI commands

If you want to control (e.g. with LabView) the device via the

TCP-Socket 5025 remotely, then pls. enable the socket server by setting the

SCPI Port parameter to 5025 in the WEBgui | Setup | pump

Configuring LabView can be found here

Escaping

LABview escaping

LABview has some difficulties to send the character <space> (ASCII char 0x20) through a TCP socket. To bypass this problem, you can use \s to escape a <space>.

Example:

showval\s-2 # will send showval -2 LABview itself will replace \s with <space> character, before sending through the TCP socket.

escaping by pump

pump will escape special characters for SCPI communication as follows:

\a # (0x07) audible bell

\b # (0x08) backspace

\n # (0x0a) line feed - new line

\r # (0x0d) carriage return

\t # (0x09) horizontal tab

\v # (0x0b) vertical tab

\xhh # arbitrary hex value hh (e.g. 0x20 ASCII space)Example:

showval\x20-2 # will send showval -2 \x20 will be replaced by ' ' *IDN?

Show the identification string of the device.

*IDN?

Output Format:

<manufname>,<prodname>,<serialnr>,<swvers> Output (Example):

BASIS GmbH,pump,0000000001234567,0.951*WAI

Synchronous wait.

*WAI

MMEM:CAT?

List all available .macro and .wave files.

MMEM:CAT?

Output Format:

<useddiskspace>,<freespace_byte>{,<filnam>,<filtyp>,<filsiz>}Output (Example):

2851360317440,935450685440,aaBeepTest,MACRO,60,aTestCtrlMacro,MACRO,105,aTestMacro,MACRO,213,dbg1,MACRO,160,dbg,MACRO,210,LowPressureTest,MACRO,79,PdfltSet,MACRO,126,StressTest,MACRO,233,TestComment,MACRO,114,TestMacro1,MACRO,139,TestStepper,MACRO,32,WaveTest1,MACRO,94Testing SCPI

The pump is e.g. reachable on IP4 address 10.8.81.109

If you want to test from a remote linux machine or mac,

open a terminal session and use preinstalled curl or nc utility.

On windows, you can use putty utility and connect via the raw socket protocol.

telnet can also be used as test utility, but needs to be installed manually.

curl -v telnet://10.8.81.109:5025

* Trying 10.8.81.109:5025...

* Connected to 10.8.81.109 (10.8.81.109) port 5025 (#0)

*IDN?

BASIS GmbH,pump,0000000001234567,0.951

^C

nc -v 10.8.81.109 5025

Connection to 10.8.81.109 port 5025 [tcp/scpi-raw] succeeded!

*IDN?

BASIS GmbH,pump,0000000001234567,0.951

^C

telnet 10.8.81.109 5025

Trying 10.8.81.109...

Connected to 10.8.81.109.

Escape character is '^]'.

*IDN?

BASIS GmbH,pump,0000000001234567,0.951

^]

telnet> q

Connection closed.- German: ctrl + ü

serial IO

alias

set an alias for a serial device.

alias <aliasname>,<devicename>

Example:

alias LabTable,/dev/ttyUSB0Predefined alias:

alias USB0,/dev/ttyUSB0

alias USB1,/dev/ttyUSB1

alias USB2,/dev/ttyUSB2

alias USB3,/dev/ttyUSB3

alias BT0,/dev/serial1Predefined alias like USB0 can be used instantly, without explicit definition.

SerRead

Read from a serial device with a TimeOut of 10sec.

serRead <interfacename> <waitforResponseString>

errorlevel:

0: if response is expected one

-1: if response is unexpected,

or device does not respond

within timeout periodExample:

serRead /dev/ttyUSB0 OK # wait for device

# response text OK

JS -1,HandleError1 # If not OK,

# Jump to Label

# HandleError1SetTTY

Set communication parameters of serial interface.

setTTY <interfacename>@baudrate [setting]

Parameter:

interfacename:

physical device path which is presented by the OS.

If an alias was previously defined, it can be used instead.

Available physical devices will be displayed under

WEBgui/Info/tty*

baudrate:

communication speed of the serial device.

Pls. consult the specific device manual.

setting:

stty command (control settings)pls. consult the linux man page for stty command (control settings): https://manpages.debian.org/buster/coreutils/stty.1.en.html

Example:

setTTY /dev/ttyUSB0@115200 clocal cread -cstopb -parenb

setTTY USB0@115200 clocal cread -cstopb -parenb set device communication parameter for /dev/ttyUSB0 speed 115200; no HW Handshake; bidirectional; 1 Stop Bit; no Parity

SerWrite

Write to a serial interface with a TimeOut of 10sec.

serWrite <interfacename> <commands>

errorlevel:

0: if commands could be sent

-1: if commands couldn't be sent

to the device within

timeout periodExample:

alias LabTable,/dev/ttyUSB0

setTTY LabTable@115200

serWrite LabTable move 300,150net2ser

socat - Multipurpose relay (SOcket CAT)

connect remote serial device to pump

net2ser <interfacename>@baudrate <ipsocket> net2ser <interfacename> stop

Parameter:

interfacename:

physical device path (e.g. /dev/ttyV00) which is presented by the OS.

If an alias was previously defined, it can be used instead.

Available physical devices will be displayed under

WEBgui/Info/tty*

baudrate:

communication speed of the serial device.

Pls. consult the specific device manual.

ipsocket:

<TCP|UDP>:<ipaddress>:<portnumber>errorlevel:

0: success

-1: invalid params

-2: baudrate not supported

-3: wrong interfacename (not /dev/ttyVxx)

-4: wrong ipsocket definition

-5: socat can not create device /dev/ttyVxx

-6: no ipsocket at remote deviceExample:

alias LabTable,/dev/ttyV00

net2ser LabTable@115200 TCP:10.8.81.119:1234

serWrite LabTable move 300,150attach serial device on server 10.8.81.119 port 1234

to local device /dev/ttyV00 with baudrate 115200

pls. make sure, that remote server 10.8.81.119 has ser2net working.

net2ser /dev/ttyV00 stopstop remote serial device

USBreset

Reset USB attached device (like USB/serial adapter).

USBreset <interfacename>

Example:

alias LabTable,/dev/ttyUSB0 # define a dev alias

# (needed only once)

USBreset LabTable # set device params

# (needed only once)WakeOnLAN

Send WakeOnLAN signal to network client.

WakeOnLAN <macaddr>

Example:

alias pc1,AA:BB:CC:DD:EE:FF # define an alias for mac address

# (needed only once)

WakeOnLAN pc1 # send wakup signal to AA:BB:CC:DD:EE:FFService Control

ButDesc

set alternate names temporarily for parser symbols.

Alternate name will appear in WEBgui and can be used as macro command.

butdesc <parsersym>[,<altname>]

Parameter:

altname: str25

str25: string with max. 25 characters

parsersym: PumpsOff,Clean,AllOff,Stby,Init,Oper,Normal,Evac,

SolALLOff,Solution1,Solution2,Solution3,Solution4,

Solution5,Solution6,Solution7,Solution8,Solution9,

SetVswitch,SetPAll,SetPON,SetPOFF,SetVRecirc,

SetVRecirc2,SetVRecirc1,SetP6,SetP7,SetP8using Unicode characters (e.g.: subscript TWO in H2O H\u2082O), pls. refer to the C/C++ / Java source code format: http://www.fileformat.info/info/unicode/char/2082/index.htm

Example:

butdesc AllOff,AllesAUS

butdesc AllOff # reset alternate name

butdesc solution1,water

butdesc solution2,H\u2082O # H2O (subscript 2)

butdesc solution3,\u6c34 # Chinese sign for water

butdesc solution4,\u0432\u043E\u0414\u042B # Cyrillic water

IniCfg

Read/Write default parameter from/to ini file pump.ini

Command execution will be checked if read/write operation is permitted.

At application startup, factory defaults can be overwritten by ini file seeded values.

Detailed information about the file pump.ini

IniCfg <section>,<key[=[value]]>

Parameter:

section: DEFAULT, HMENU_DEFAULT, HOME, SENSOR, PUMP

key: ini file key

value: ini file value 0: off 1: onExample:

IniCfg HMENU_DEFAULT,BUTTONBEEP # read button beep value (omit=)

IniCfg HMENU_DEFAULT,BUTTONBEEP=0 # switch button beep off (write)

IniCfg HMENU_DEFAULT,BUTTONBEEP= # reset value to factory defaultIPShow

Will show systems IP address on WEBgui.

On OLED display it will show a QRcode with access information.

IPShow [<idx>]

Parameter:

idx: 0 - 2

0: WLAN0 (default) # wlan interface

1: ETH0 # ethernet interface

2: AP0 # hotspot interfaceExample:

ipshow # show wlan0 access info

ipshow 2 # show hotspot access infoPwrOff

Shut down system.

PwrOff

Reboot

Reboot system.

Reboot

Restart

Restart pump program.

Restart

ResetDflt

Will reset SetPoint and Standby pressure values to factory defaults.

ResetDflt

saveSetP

Will save SetPoint pressure values as default.

saveSetP

saveSTBY

Will save Standby pressure values as default.

saveSTBY

setPar

Set global Parameter

setPar <param1>,<param2>,<param3>...

Parameter:

Solution:

param1: Solution1 ... Solution9

param2: Pulse

param3: <number>Example:

setPar solution1,Pulse,1.23 # set pulse for Manifold1 to 1.23 seconds

setPar solution1,Pulse,0 # reset pulselength for Manifold1showREG

Show register content

showREG <register>

Parameter:

register: -1 .. 9Example:

showREG -1 # show errorlevel

showREG 3 # show content of register 3showSNR

Will show the serial number of the device on the OLED and WEBgui.

showsnr

showVAL

Show value

showval <fieldnum>[,<idx1>[,<idx2>[,<idx3>[,<idx4>]]]]

Parameter:

idx: 1 .. 8 # field[idx1]

idx2|3|4: # for selecting sub fields, within a separated list

fieldnum: -30 .. 1

1: Profile Oper

0: Profile Stby

-1: Profile last

-2: SetPoint (SetP)

-3: ProcessValue (PV)

-4: ProcessValue averages (PVavg)

-5: default values

-6: minimum values

-7: Stby values

-8: reservoir type (-1:vacuum, 0:disabled, 1:pos. pressure)

-9: Stby values

-10: Init values

-11: Clean values

-12: reservoir indexes

-13: reservoir description

-14: reservoir title

-15 .. -20: (reserved range, for future use)

-21: Menue info PSET

-22: Menue info OPS

-23: Menue info SVC

-24: Menue info SOL

-25 .. -29: (reserved range, for future use)

-30: Manifold states [idx1: 1-6]Example:

showVAL -2 # show SetPoint values for all reservoirs

showVAL -2,3 # show SetPoint value for Reservoir 3

showval -21 # "PAll,%,VSET_Float,0|-25.0|25.0|0.5|1","P1..."

showval -21,1 # PAll,%,VSET_Float,0|-25.0|25.0|0.5|1

showval -21,1,4 # 0|-25.0|25.0|0.5|1

showval -21,1,4,2 # -25.0showVER

Will show the firmware version of the device on the OLED and WEBgui.

showver

SWUpdate

swupdate

System will download and install new available Firmware.

System needs to be connected to the internet.

A valid license is required.

Valve Control

SetVBleed

Set available bleed valves Open/Close.

An optional module is required.

setVBleed <setstring>

Parameter:

Valve: 1 - 2

0: CLOSE

1: OPEN

x: unaffectedExample:

setVBleed 0,x # set Valve#1 CLOSE

# let Valve#2 unaffectedSetVClean

Set available cleaning valves Open/Close.

An optional module is required.

setVClean <setstring>

Parameter:

Valve: 1 - 3

0: CLOSE

1: OPEN

x: unaffectedExample:

setVClean 0,x,1 # set Valve#1 CLOSE

# let Valve#2 unaffected

# set Valve#3 OPENSetVRes

Set available reservoir valves Open/Close

setVRes <setstring>

Parameter:

Valve: 1 - 8

0: CLOSE

1: OPEN

x: unaffectedExample:

setVRes 0,x,1,0,1,0,x,x # will set Valve#1,4,6 CLOSE

# let Valve#2,7,8 unaffected

# set Valve#3,5 OPENSetVProp

Set available proportional valves to a value between 0 and 1.

An optional module is required.

setVProp <setstring>

Parameter:

Valve: 1 - 2

vrange%: 0 - 1.0 (0V - 5V)Example:

setVProp 0.1,0.5 # set Valve#1 to 10% (0.5V)

# set Valve#2 to 50% (2.5V)Valve

Set available manifold valves Open or Close

Valve <setstring>

Parameter:

Valve: 1 - 8

0: CLOSE

1: OPEN

x: unaffectedExample:

Valve 0,x,1,0,1,0,x,x # will set Valve#1,4,6 CLOSE

# let Valve#2,7,8 unaffected

# set Valve#3,5 OPENOLED functions

OLED functions can only activated at the device directly.

FctryDflt

Will reset systems hostname, WLAN, passwords and time zone to factory default.

CreaSupFil

Create a supportfile, which can be uploaded by UplSupFil command.

ExpMacro

Export all .macro and .wave files from the system to a connected USB stick.

The files will be copied to sticks /pump/macro directory.

!!! Files with same name will overwrite files on USB stick !!!

Requirement:

- writeable USB stick labelled with PUMPImpMacro

Import all .macro and .wave files from the connected USB stick.

The files will be copied from USB sticks /pump/macro directory to the systems macro directory.

!!! Files with same name will overwrite files in systems macro directory !!!

Requirement:

- readable USB stick labelled with PUMPPDrctMod

Pressure direct mode.

Parameter:

PDrctMod off:

SetPoint will be activated after pushing encoder wheel switch.

PDrctMod on (indicated on OLED display with 'd'-flag):

SetPoint value will follow encoder wheel turns synchronously.SetPAll

changes all reservoir SetPoints by PAll percentage at once.

P1: 100mbar

P4: -50mbara e.g. 10% PAll value will increase P1 from 100mbar to 110mbar, P4 (vacuum) will be increased to -55mbar.

SetWlanUSB

WLAN Setup with USB Stick

- use a preformatted USB Stick, which is labelled with PUMP

- place a prepared text file wlanset.txt in top level directory

- Power up the system

- Plug USB Stick into an available USB Slot

- Turn the encoder wheel left until SVC (Service Menu) will appear and activate it by pushing the wheel

- In selected SVC menu, turn the wheel left, until function SetWlanUSB appears and select it

- The pump will write a file /pump/cfg/pumpinfo.txt onto the USB Stick

- If everything went ok, an automatic reboot will be initiated

- Pump will try to connect to your WLAN with given configuration

- If Pump cannot connect to your WLAN, pls. investigate written file

/pump/cfg/pumpinfo.txt you will find useful information like WLAN MAC-Address, SerialNr …

Configuration file has 3 lines:

- Line: <YourWlanSSID>

- Line: <YourWlanPassword> and further wpa_supplicant.conf specific data, each separated by ; (semicolon).

- Line: Your two letter country code (e.g. SE DE …)

Example file content (/wlanset.txt):

MyWLANname

psk="MyWLANPassword";proto=WPA2;key_mgmt=WPA-PSK

DEDetailed information for wpa_supplicant.conf can be found here:

https://linux.die.net/man/5/wpa_supplicant.conf

UplSupFil

uplsupfil

Upload support file, which was previously created by CreaSupFil command.

Requirement:

- system needs to be connected to the internetUSBLic

usblic

Load license from USB stick.

Requirement:

- readable USB stick labelled with PUMP

- license is placed in USB sticks /pump/<snr>/ directory

- serial number is part of the license file name

format: lic_<snr>.lic

e.g. /pump/10000000556fabcd/lic_10000000556fabcd.lic

- valid support contractIf internet connection is available, pls. use WWWLic instead.

WWWLic

wwwlic

Load license online.

Requirement:

- valid support contract

- system needs to be connected to the internetData Access

Instead of using Avahi/Bonjour hostname (pump.local),

pumps IP Address (e.g. 192.164.1.123) can be used.

For login pls. use user admin credentials.

FTP

Connecting to pump via FTP client (e.g. FileZilla client).

If FTPES is not working, try ‘Only use Plain FTP’.

More info and downloading FileZilla client:

TCP Socket

The device can start a basic TCP socket server process which which will offer the ability, to control the pump over IP network.

Every command described in chapter Command reference can be used.

Enable device TCP socket can be found here

register device:

create new device for remote control.

using pump device’s IP address or hostname and the connection port (e.g. 5025)

comm setting:

pump will expect, that each message is terminated by a line feed (\n or hex value 0x0A).

Set communication timeout to 2 seconds.

comm tests:

Query pumps ID string with SCPI command *IDN?

Terminate command with \n

Query pumps macro directory content with SCPI command *MMEM:CAT?

Terminate command with \n

USBsync

is a background service, which will run every hour.

The service will backup important files to an attached formatted USBstick.

All copied data can be found below the USBstick /pump/

The listing of all contents on the USBstick can be found under the

Info menu /media/usb Tab.

WebDAV

Mounting the following directories with user admin, as shared network devices:

| Dir | WebDAV link | Description |

|---|---|---|

| bck | http://pump.local/bck | up-/download config backups |

| macro | http://pump.local/macro | up-/download or edit macros |

On a MAC system, use Finder and connect with server <command> K

https://help.dreamhost.com/hc/en-us/articles/216473527-Accessing-WebDAV-with-Mac-OS-X-and-Linux

On Windows (7 - 10):

https://help.dreamhost.com/hc/en-us/articles/216473357-Accessing-WebDAV-with-Windows

Hardware

DB9 connectors

X1 multipurpose Digital IO

Every DIO pin can be configured as an independent input or output.

Beside the simple DIO function, some Pins can have special functions like Pulse Wide Modulation (PWM), which can be used for stepper, DC motor or servo control.

|

Description | Command |

|---|---|---|

| 1 | Step motor | STP, SERVO#1 |

| 2 | DC motor | DCMx, SERVO#2 |

| 3 | X10 | X10, X10mode, DOut#1, DOutM |

| 4 | Step direction | STPdir, DOut#2, DOutM |

| 5 | Step enable | STPenable, DOut#3, DOutM |

| 6 | Trigger OUT | SyncOut, DOut#4, DOutM |

| 7 | Trigger IN | WaitSync |

| 8 | VCC (+5V) | |

| 9 | GND |

All signals are TTL (5V) compatible and can drive up to 50mA per pin.

Signal pins are ESD 15kV protected.

Used interface chip: TXB0108 (see datasheet for further information)

as servo, use e.g. SG90, MG90S, MG996R or any other servo.

as stepper motor driver, use something like:

Quimat Nema 17 stepper driver

X2 Manifold digital output

If internal Manifold module is not used, an external Manifold can be connected.

If a Manifold is not used at all, these pins can be used as simple independent TTL outputs.

|

Description | Command |

|---|---|---|

| 1 | Manifold 1 | Solution1 |

| 2 | Manifold 2 | Solution2 |

| 3 | Manifold 3 | Solution3 |

| 4 | Manifold 4 | Solution4 |

| 5 | Manifold 5 | Solution5 |

| 6 | Manifold 6 | Solution6 |

| 7 | VCC (+5V) | |

| 8 | not connected | |

| 9 | GND |

All signals are TTL (5V) compatible and can drive up to 500mA per pin.

Used interface chip: ULN2803A (see datasheet for further information)

The ULN2803 series are high-current arrays with NPN darlington pairs.

All pins feature integral clamp diodes for switching inductive loads,

which can be connected between VCC and the output pin [1-6].

Mobile devices

The pump’s webserver supports the Web Application Manifest,

which allows to create a screen icon to open pump’s webgui in fullscreen mode with on click.

iOS

fullscreen (kiosk) mode

For adding a home screen icon for pump’s webgui,

simply follow the steps below on your iOS-enabled device

(such as an iPad or iPhone):

- Open the Safari browser and go to pump’s webgui.

Instead of an IP-address (e.g. 10.8.90.123),

use the mDNS/bonjour/avahi entry pump.local

If you have a working DNS infrastructure, use pump’s

fully qualified DNS entry, like pump.mycompany.com

- Click the share icon in the browser

- Select the option ‘Add to Home Screen’

- On the ‘Add to Home’ page you should be able to see the icon for pump’s webgui and url, press add button.

- On your screen you should see a newly created icon

- push the icon and you will get pump’s webgui in fullscreen (kiosk) mode.